In today’s world, sustainability and environmental responsibility have become major concerns for individuals, governments, and industries. An area that stands out for its positive impact on the environment is the recovery of precious metals from catalytic converters. These small but valuable components, found in almost all vehicles with internal combustion engines, play a vital role in reducing harmful emissions. However, they also contain precious metals such as platinum, palladium, and rhodium, which are rare and expensive to mine. The recovery of these metals from spent catalytic converters offers significant environmental benefits, from reducing resource extraction to minimizing pollution and promoting a circular economy.

Understanding Catalytic Converters and Precious Metals

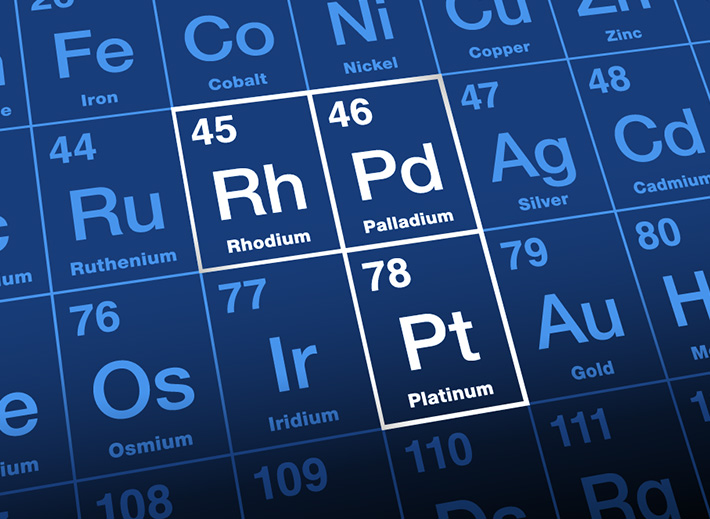

Catalytic converters are devices integrated into the exhaust systems of vehicles to reduce harmful emissions, such as carbon monoxide, hydrocarbons, and nitrogen oxides, which contribute to air pollution and smog. They work by using catalysts, usually precious metals such as platinum (Pt), palladium (Pd) and rhodium (Rh), to convert these toxic gases into less harmful substances such as carbon dioxide, nitrogen, and water vapor. These metals were chosen because of their excellent catalytic properties. However, they are not only rare, but also expensive to mine and process. The demand for these metals is high, and the process of extracting the land carries significant environmental costs, including habitat destruction, energy consumption and pollution from mining operations.

The Environmental Impact of Mining Precious Metals

Before delving into the benefits of recovering precious metals from catalytic converters, it is important to understand the environmental consequences of traditional mining methods. Precious metals such as platinum, palladium and rhodium are often extracted from deep within the earth in a process that requires substantial amounts of energy and water. This process involves extensive open pit or underground mining, which often leads to ecosystem destruction, deforestation, and displacement of local wildlife. In addition, mining operations release a significant amount of carbon dioxide and other greenhouse gases into the atmosphere, contributing to global climate change. The process also generates a large amount of waste which, if not managed properly, can lead to water, and land pollution due to the release of toxic chemicals used in the processing of minerals. With platinum and palladium mainly mined in regions such as South Africa and Russia, the environmental impact is further compounded by transport requirements, which add to the overall carbon footprint. With the increase in demand for these metals, the pressure on the environment also increases, making it necessary to look for alternative sources of these materials.

Recovering precious metals from used catalytic converters provides a sustainable and eco-friendly solution to the problems posed by traditional mining. Here’s how:

The most immediate environmental benefit of recycling catalytic converters is to reduce the need for new mining operations. Instead of mining new reserves of platinum, palladium and rhodium from the ground, these metals can be recovered from used car parts. This helps to conserve limited natural resources, reduce environmental degradation associated with mining, and reduce the need for land disturbance.

For example, a single catalytic converter can contain between 3 and 7 grams of platinum group metals (PGM). When you multiply this figure by the millions of vehicles scrapped each year, the recovery potential becomes significant. By recycling these materials, we can significantly reduce the environmental burden of extracting new metallic minerals.

The catalytic converter recycling process requires much less energy than traditional mining and refining operations. Precious metal mining is an energy-intensive process that involves blasting, drilling, transporting, and refining the minerals. In contrast, the recovery of metals from catalytic converters involves specialized processes such as smelting and refining, but these are more efficient and less resource intensive than the extraction of new metals. According to some estimates, recycling platinum from waste requires only 10% of the energy needed to extract the same amount of virgin ore. This results in a lower carbon footprint, which helps industries and nations meet their emission reduction goals while continuing to supply the market with needed metals.

Another major environmental benefit of recycling catalytic converters is the reduction of waste. Used catalytic converters otherwise end up in landfills, contributing to the growing problem of electronic and automotive waste. By recycling, we not only reduce waste going to landfill, but we also recover valuable materials that would otherwise be lost. Recycling precious metals also promotes resource efficiency. Since the metals used in catalytic converters are limited, efficient utilization and recovery becomes essential. Recycling programs enable a closed system in which metals are reused repeatedly, reducing the need to extract new materials, and ensuring that precious resources are not wasted.

Recycling catalytic converters helps mitigate various forms of pollution. By reducing the need for mining, we minimize the pollution associated with mining activities, such as the contamination of water and land with toxic chemicals and waste byproducts. Mining operations often produce tailings (residues left after metals are extracted from ores) that can flow into nearby water bodies, causing significant ecological damage. On the other hand, the recycling process is much more controlled and produces less pollution. Modern recycling facilities adhere to strict environmental regulations and use advanced technologies to minimize emissions and hazardous waste, ensuring that the process is as clean and sustainable as possible.

Catalytic converter recycling plays a vital role in promoting a circular economy, a system in which materials are reused and recycled, minimizing waste and making the most of existing resources. This contrasts with the traditional linear economy, which follows a “take, make, throw away” model that often leads to resource depletion and environmental damage. By recovering precious metals from catalytic converters, we can reduce the demand for virgin materials, conserve precious running resources and create a more sustainable automotive industry. This not only reduces environmental damage, but also creates economic opportunities in the recycling sector, creates jobs and promotes green growth.

The recovery of precious metals from catalytic converters offers significant environmental benefits that cannot be overlooked. From reducing the use of harmful mining practices to conserving energy and resources, the recycling of these components plays a crucial role in building a more sustainable future. By adopting catalytic converter recycling on a wider scale, we can move towards a greener and more circular economy that prioritizes resource efficiency and environmental protection. For individuals, car manufacturers and policy makers, investing in and supporting catalytic converter recycling programs is a step in the right direction that reduces environmental impact while ensuring a continuous supply of essential materials for the industries that depend on it. In a world where the pressure on our planet’s resources is only increasing, every effort to recover and reuse valuable materials matters.

Are you a used catalytic converter wholesaler, supplier, dealer or secondary recycler, looking to maximize the precious metals profits from your scrap catalytic converter recycling business? CLICK HERE NOW TO LEARN MORE

Get in touch with our team by submitting the form below.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.